The oldest and most commonly used type of crusher that crushes soft limestone from limestone beds or stone quarries to the hardest basalt is called a jaw crusher. The movable jaw, which performs the crushing action, is suspended from the body through an eccentric drive shaft and supported by a safety plate attached to the crusher body.

The movable jaw moves in an elliptical motion close to a circle at the feed opening and in a narrow ellipse close to a straight line at the discharge region. This allows the material to be grasped and crushed on the upward motion and gain momentum to exit the discharge opening, thus facilitating material flow. It is nearly impossible to achieve the desired product size using a single crusher. Jaw crushers can be used both as primary crushers, which crush the material into coarse fragments, and as secondary crushers to refine the material. The feed opening of secondary jaw crushers is narrower compared to primary crushers. Factors such as the material to be fed, desired product sizes, and hourly production capacity are decisive factors in crusher selection.

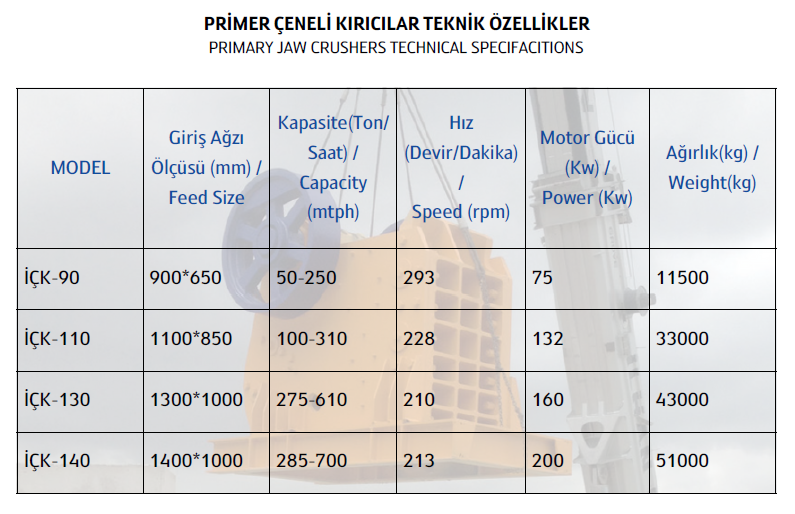

The graphs and tables related to these factors are provided below. The feed opening between the jaws should be selected larger than the maximum size of the material to be fed. This will prevent large stones from causing blockages in the opening and increase capacity with continuous feeding.

To ensure the desired average capacity, the crusher is selected above theoretical values, taking into account losses that may arise from feeding and other disruptions during operation.

Our jaw crushers offer unique operational advantages to users due to their high flywheel speeds, jaw nip angles, special geometries of pitmans with safety plates and rear blocks, as well as their high performance, reliability, durability, and user-friendly adjustment mechanisms.

All İmza Machine jaw crushers are equipped with a hydraulic-assisted adjustment mechanism. This system enables easy and quick adjustment of the jaw lower clearance according to the desired product curve you want to achieve from the machine.

The adjustment of the jaw lower clearance is done by adding or removing adjustment plates of the required thickness behind the adjustment block, which is pushed forward with a manual or hand-operated hydraulic system. This system not only allows for a wider range of adjustments compared to other mechanisms but also ensures greater reliability. On the other hand, both the fixed and movable jaws are made of manganese steel and designed to be rotatable, ensuring that their contact surfaces do not get damaged and they are resistant to fractures that may occur due to stress throughout their working lifespan.

The crusher shafts are made of forged steel and supported by spherical roller bearings. The bearings are grease-lubricated and protected against external influences with labyrinth seals. Crushers can be equipped with an optional automatic lubrication system.

To protect the machines from unintended iron pieces that may escape with the fed material, the machine's support plates (safety plates) are made of cast iron and designed to break under excessive load, allowing the iron piece to pass without causing damage to the rest of the machine structure. The support plate slots are designed as self-lubricating type and easily replaceable.